nZEB life cycle processes

In order to be able to optimise nZEB related processes, project specific roles, interactions, tasks and schedules, depending on the stakeholder perspective, must be known. Building owners, investors, tenants, construction companies and planners have different interests and are involved in different phases in the life cycle of buildings. There is a general lack of understanding, transparency and uniform methods when it comes to the process of nZEBs.Clear and comprehensive life cycle processes are needed to ensure goals (both cost savings and energy) are met in a cost-effective manner. The following chapter presents a framework for ensuring the process quality in the life cycle of nZEBs. It outlines the key actions needed to ensure the achievement of energy and cost related goals presenting an optimal replicable planning, design, construction, and operation process. More information can be found in the CRAVEzero process reports.

Figure 23: Vala Gard – Skanska Sweden

In addition to legal and urban boundaries, buildings are essentially defined by owners and investors. Technical quality and high comfort standards have to be achieved within project specific budget limitations. Architects and specialized planners typically translate the client’s ideas and wish into real plans and are responsible for the appropriate execution of the building project. Construction companies and craftsmen from numerous different disciplines are involved in constructing the building. There is a constant coordination process between the client, the planners and the contractors to prepare the construction of a building and if necessary, to react to changing conditions like costs, schedules, requests from the client, weather, etc. (Arnold 2005). The range of services provided to buildings in the urban context today has also changed over time and gained new aspects. Nearly zero energy buildings increasingly become active participants of our energy supply infrastructure and raise new challenges concerning the quality of planning, construction and operational phase of a building. This results in innovative energy concepts for both buildings and the districts. Innovations related to the realization of nZEBs arise in different life cycle phases of buildings and at different points of the value chain in the building industry. To reduce costs, accelerate processes and assure the quality of nZEBs the right decisions have to be taken at the ideal time within the overall process. In the early stage of building design, it is easy and inexpensive to make significant design changes to reach the best solution. Each design stage adds more and more details to the project, so it becomes more challenging and costly to make changes during the progression to further stages. Traditionally, during the design process for a building’s energy system, the architects send the initial building designs to engineers, who then test out a variety of energy system scenarios for a few weeks. During the time, when the engineers can come back with an analysis, the architects have often made significant design changes. This process can not only lead to less-efficient and more-expensive HVAC systems, renewable energy systems and envelope qualities, but usually leads to longer project timelines, unexpected construction issues, delays and budget overruns. The following process-framework developed in the CRAVEzero project makes it easier, faster and therefore cheaper to plan new nZEBs by helping to identify the most cost-effective and energy-efficient solutions and business models, all while reducing the risks of redesign, delay and budget overruns by optimizing overall processes.

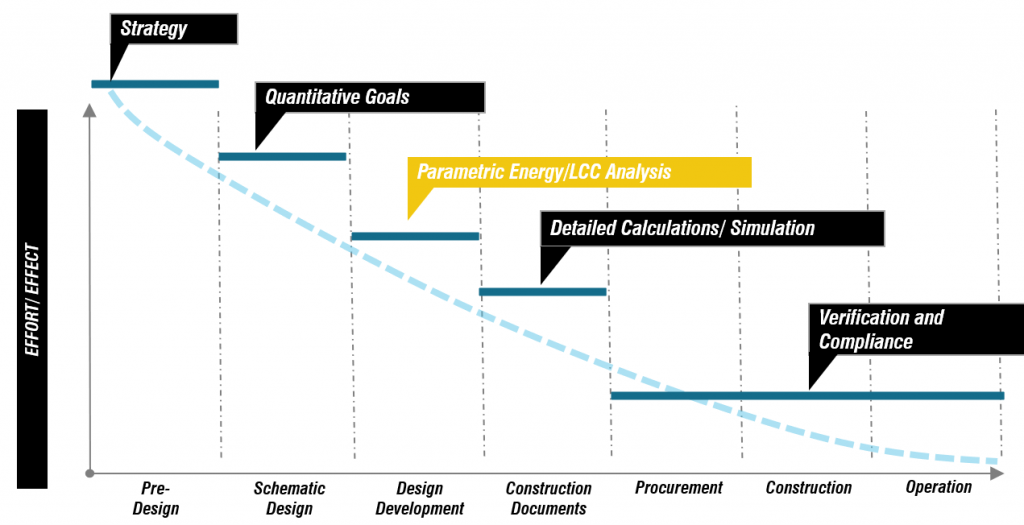

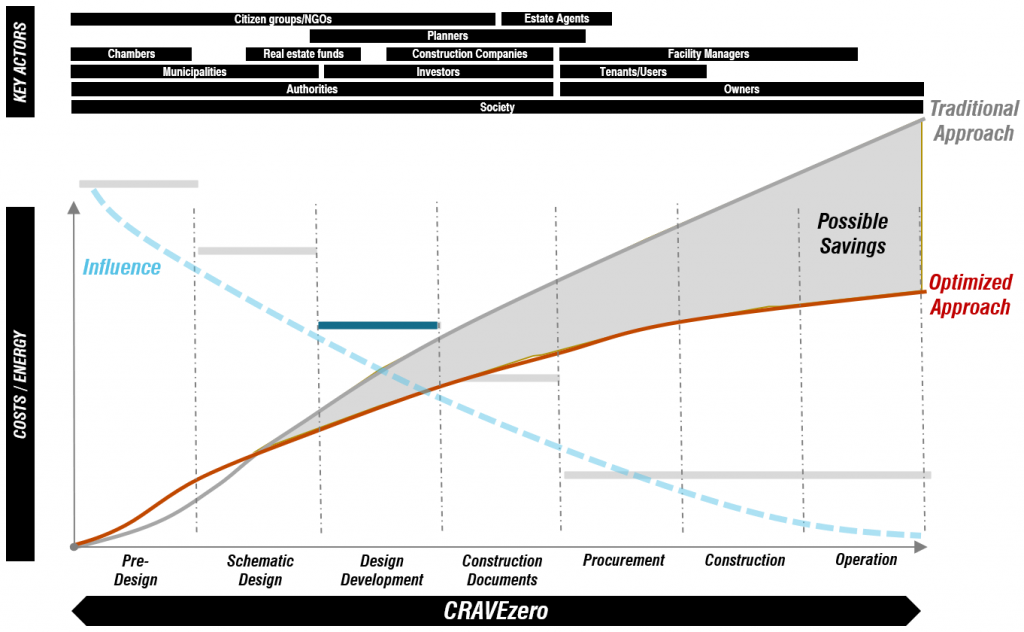

Figure: Influence, measures and decisions in the individual phases of the buildings’ life cycle

The Figure, is based on the MacLeamy curve (IDEAbuilder 2012). It shows how the effort and cost of design changes can be minimized at an earlier stage of the design process when the effect can be maximum. The aim is to facilitate the integration of building energy and life cycle cost calculations in the early stages of the building design. The MacLeamy’s curve is a well-known concept of how shifting decision making in building design early into the process leads to great benefits in building performance and cost. It is very costly to change the technical solution sets to reach nZEB at a late design stage. Hence, early-stage energy and life cycle cost analysis is vital for cost-effective nZEBs.

Figure: Decisions in the early phases of project development have a strong influence on life cycle costs

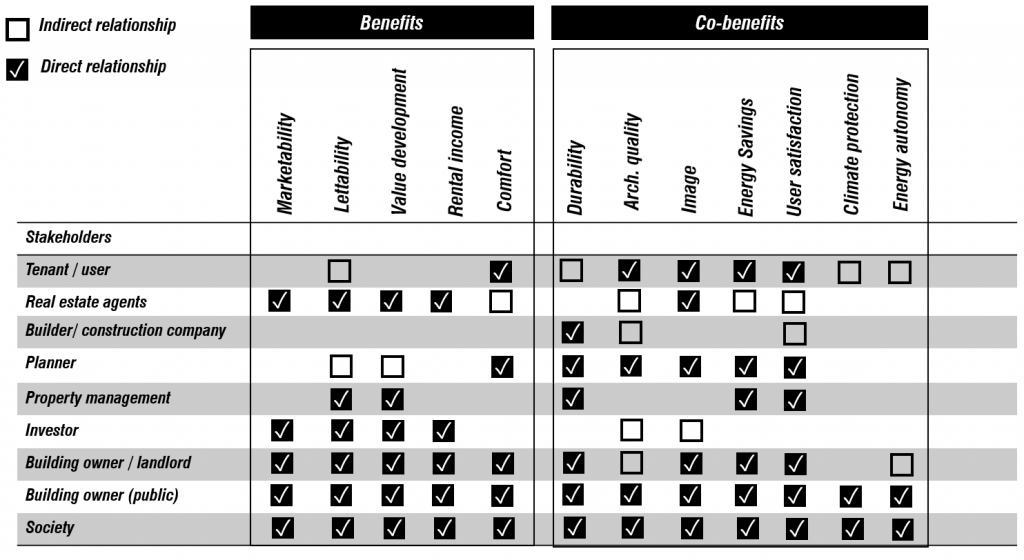

Figure: Stakeholders’ influence in nZEB life cycle phases

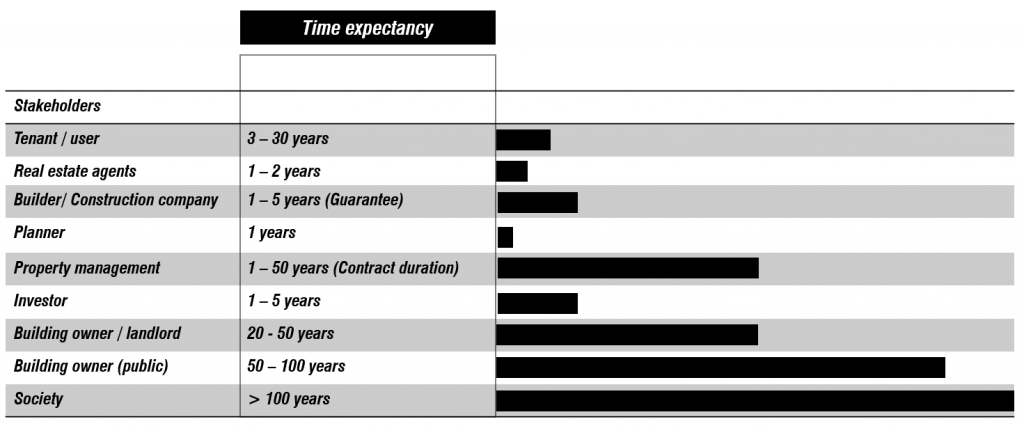

In the life cycle of a building, there are different interests of the actors and derived from this also different perspectives, observation periods and target values. There is the tenant/user, the real estate agent, the building contractor, planner, property manager, investor, owner and also the company which is directly or indirectly involved in the building process. These actors are involved in the overall process over a certain period of time. While the tenant is primarily interested in the operational phase, the planner is usually more likely to deal with the building only until its completion. If a property is financed and used by the resident himself, the entire life cycle up to a change of use is usually of interest. Depending on the approach, this can be between 25 years, after repayment of the bank loan, and up to 50 years, after increased consideration of the use. For society as a whole, the entire service life of a building, including its demolition and disposal, usually counts. This can also be shown in the influence and interest of stakeholders in different life cycle phases. The period under consideration must, therefore, be determined in advance with the parties involved. For most of the considerations of the entire building, between 25 and 50 years have proven to be reasonable.

Figure: Stakeholders’ time expectancy of a nZEB project

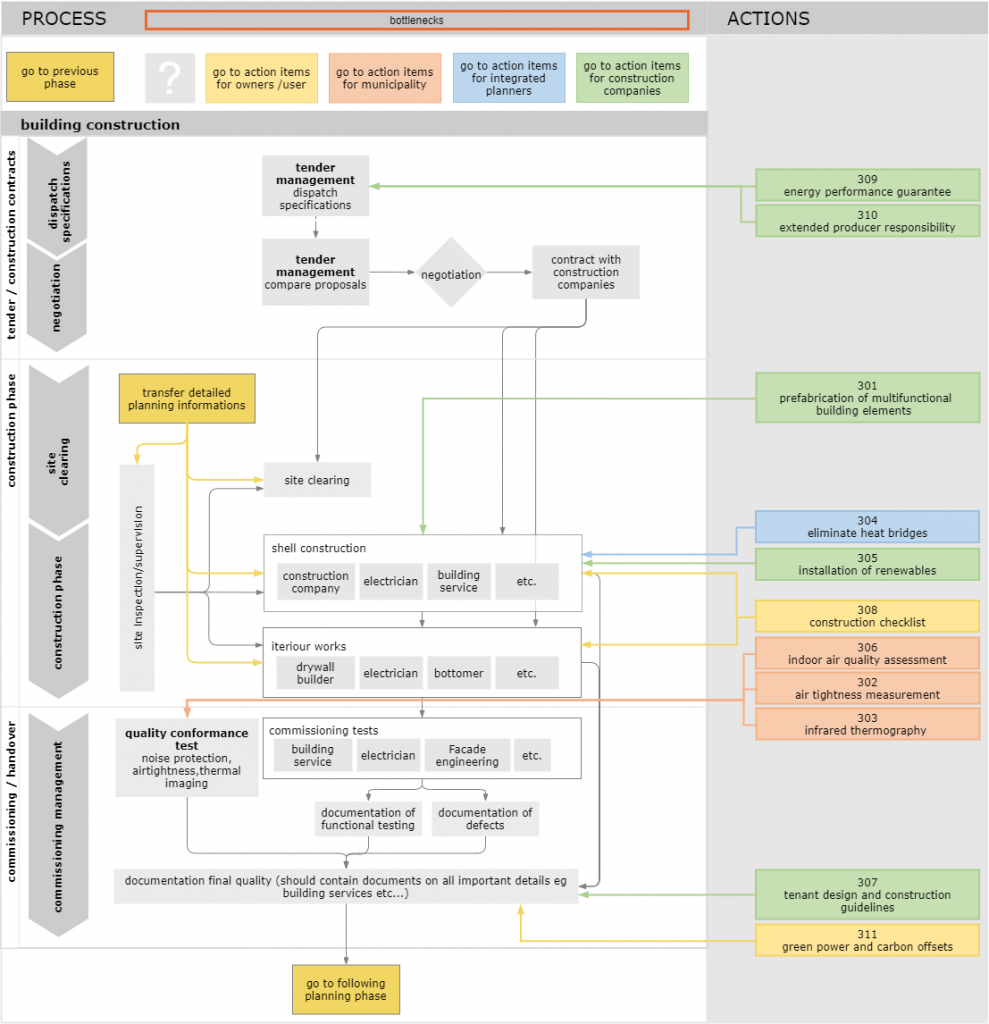

This chapter describes the “CRAVEzero process”, a common, interdisciplinary framework of nZEB life cycle processes for all involved stakeholders. This well organized and transparent process is the key to achieving the goal of cost-optimal and sustainable nZEBs throughout the entire life cycle. The complexity of nZEB related processes is one of the main reasons why nZEB developments fail in the planning, construction or later on in the operational phase. Already from the very beginning, pre-requisites must be created in order to define the requirements and clear project objectives. Too often, promising building concepts fail to achieve costs and energy goals because project participants are not sufficiently aware of the manifold interactions of holistic planning contexts.

The process of nZEBs

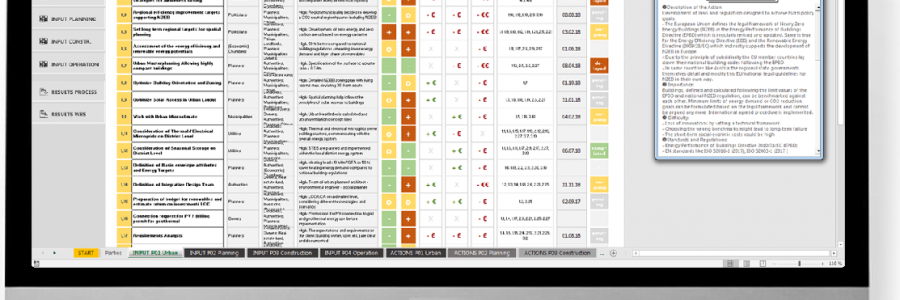

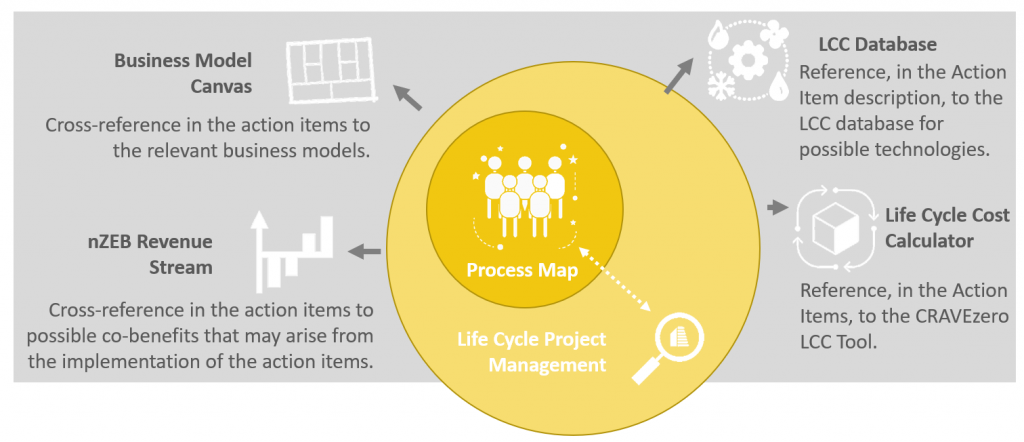

Figure: The CRAVEzero process and its connection to the CRAVEzero pinboard

Each building has its unique process, where architects often start from scratch, collect the information and constraints of the local context, develop the building, carry out cost-optimal performance analyses, hopefully include an evaluation of the potential for using renewable energy. This means extra costs for the design process. Stakeholders repeat almost the same procedures without a coordinated

and standardized process. As a starting point, an organized framework for a systematic approach for the life cycle process of low-cost nZEBs is needed. A clear connection between the building performances and the related costs is essential for ensuring the clarity of the process. A strategic element in the whole process is the introduction of a performance-based procurement approach as a common practice not only for public tendering but also for private construction.

In order to minimize risks and possible bottlenecks, obstacles must

be identified at an early stage. It is necessary to establish a common planning understanding for nZEBs among all actors early on. The design of new nZEBs begins with maximizing passive design, yet limiting energy consumption from the grid. To do this, planners often need to challenge the norms of traditional designs. In the life cycle of a building, there are different interests of the actors and derived from this also different perspectives, observation periods and target values. There is the tenant/user, the real estate agent, the building contractor, planner, property manager, investor, owner and also the company which is directly or indirectly involved in the building process.

CRAVEzero Life cycle process

phases

To achieve the nZEB goal at reduced costs, additional strategies and refinements of existing planning, construction, operation and maintenance practices are required. In CRAVEzero, a process has been developed to highlight the changes in a common practice. This implies that a standard process for the life cycle (from planning to demolition) is mapped and supplemented with key information. The CRAVEzero Process Map and the associated CRAVEzero Process Tracker outlines the key actions required to ensure the achievement of energy and cost related targets through repeatable planning, design, construction and operational processes. The development of a clear and comprehensive lifecycle process that includes specific and measurable actions (both cost savings and energy savings) is crucial to ensure that the targets are met cost-effectively. The CRAVEzero process is the centerpiece of this research project. In the graphical representation of the process map, all participants in the building life cycle can identify their role and recognize their tasks and obstacles. The tools, methods and information developed in the research project can be accessed via the process map. The user can find the following information in this CRAVEzero Process Map:

- Existing process: The “CRAVEzero Process-Map” describes the overall process and steps to

be taken for all related stakeholders for all phases of a project’s lifecycle - Actions: Tasks

/ actions were identified which lead to the ability to plan, build and operate

a nZEB. These activities were assigned to stakeholders and already existing

process steps. - Process evaluation results: Actions are assigned to the main drivers and

other stakeholders to clarify the question of responsibility. In addition, the

correlations between all actions and stakeholders are shown. - Pitfalls and bottlenecks: Pitfalls and bottlenecks that can endanger deadlines, budgets and

quality of the nZEB project.

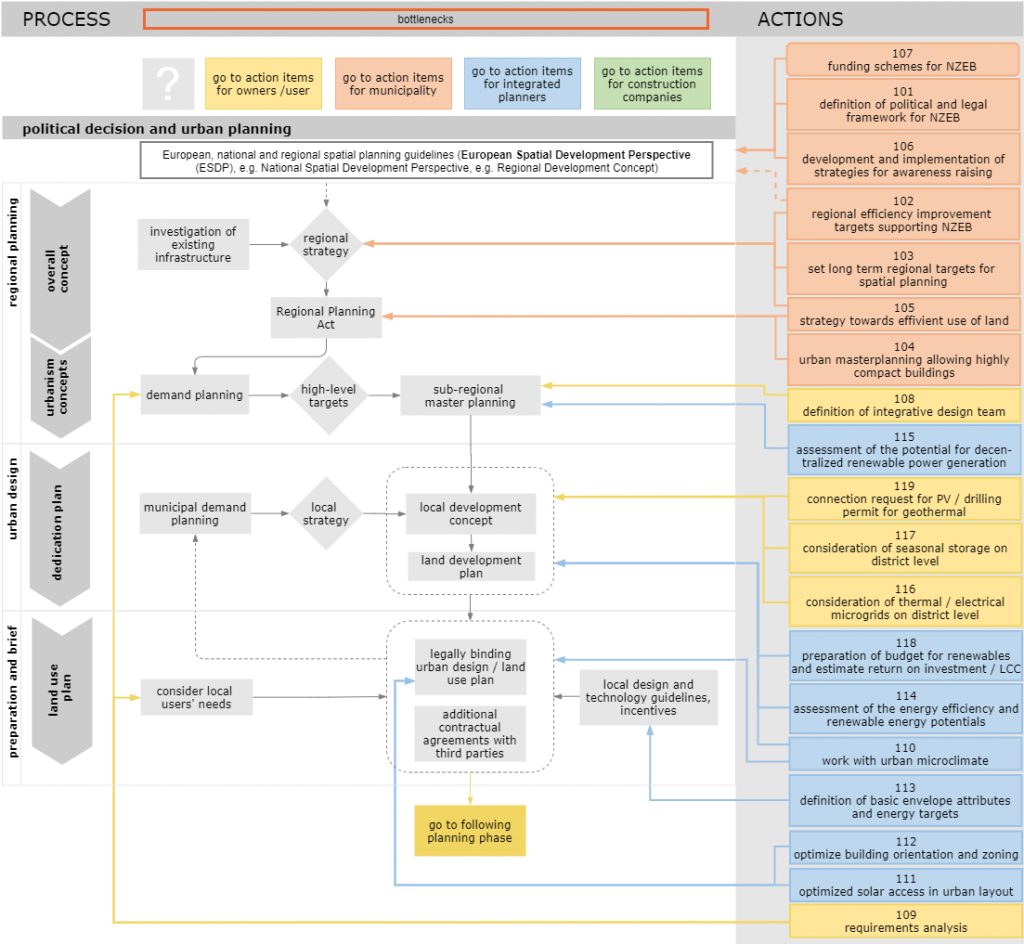

Urban Planning

The political decision and urban planning process lays the foundation for all upcoming phases of new nZEBs. It is in this phase that the common interest for low emission and low cost for public services is considered.

Political decisions and urban planning are usually done proceeding from a large Scale (e.g. regional planning) towards a local scale.

The main tasks on

each decision and planning level are:

- Investigation and analysis of

the existing situation - Definition of a strategy

- Consideration of demand

- Definition of targets for

spatial order - Documentation and

implementation of strategy and targets

These documents may come in the form of plan material, regulations, laws, treaties with third parties, e.g. energy suppliers, landowners etc. The documents may be legally binding or hold recommendations for further planning on a more detailed level. Several actions can be taken on a regional planning level to promote nZEBs. These include the definition of the political and legal framework, as well as offering funding schemes and awareness raising. Also, the definition of targets is an important action on the regional level, since regions can often be linked to specific climates which again have an impact on the building design. Actions can have the intention to encourage, enable or enforce. The focus of urban design in the context of nZEBs is on environmental conditions like sunshine, microclimate and wind lanes, and infrastructural conditions at a neighborhood level. Infrastructural conditions on neighborhood or district level include thermal and electrical microgrids, seasonal storage as well as renewable energy use and building envelope attributes and targets.

It is important to be aware of the common pitfalls that can compromise project success in the urban planning phase. Below, pitfalls and bottlenecks are listed that can endanger deadlines, budgets and quality of the nZEB project during the urban planning phase. The most common pitfalls and bottlenecks are:

- Demand planning in the urban

planning phase - Investigation of potentials for

renewable energies at the site - Political support / incentives

- High demand for housing

- Development goals do not

correspond to nZEB standard

The political decision and urban planning phase are layered into different levels. It is of uttermost importance that the interdependencies between these levels work well: That means that there have to be well-defined and checked mechanisms for information exchange between the levels. For example, it makes no sense to offer subsidies for certain energy supply systems on a regional level if, on a local level, other systems are preferred. Moreover, in some cases, it can be useful to integrate actions on different levels. A joint planning team of regional, urban and energy planners could, e.g. better integrate interests both of urban population and extra-urban environment.

Figure: Optimal CRAVEzero nZEB urban planning process with stakeholder-related actions

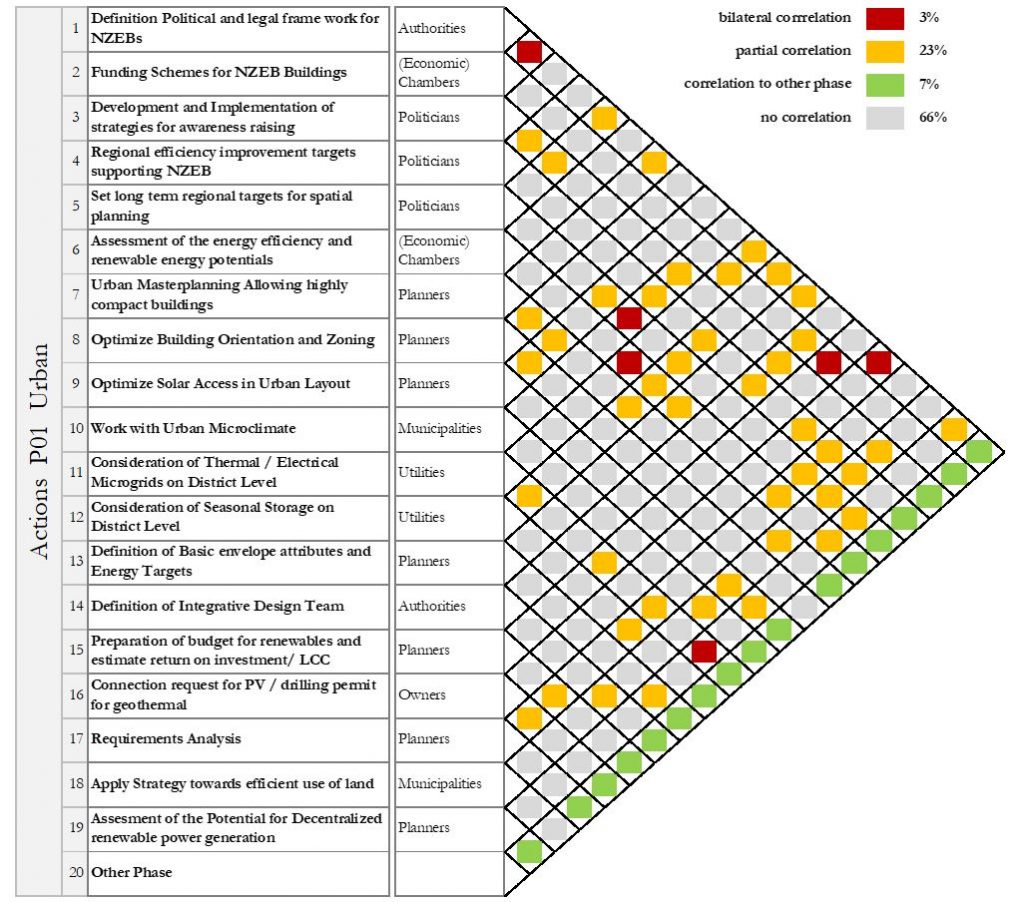

A detailed description of the individual actions in this phase and the overall optimal urban planning process (Figure 29) can be found in the report: Guideline I – nZEB Processes. To ensure the successful cooperation of the stakeholders, it is important to show the interdependency of individual nZEB-related actions in this phase to other stakeholders and actions. The following figure shows the dependencies of the different actions. This visualization (Figure 30), shows interdisciplinary relationships in order to achieve a common understanding of planning based on a workshop with stakeholders within the project. In addition to the different actions of the phase to be considered, the main responsible actors are listed to obtain a quick overview. The colored fields describe the dependencies of the different actions on each other. The red fields describe a bilateral, while the blue fields describe partial correlation (e.g Action 1 “Definition of political and legal framework” has a bilateral correlation, marked in red with Action 2 “Funding Schemes for nZEBs).

Figure 30: Urban planning process with stakeholder-related actions

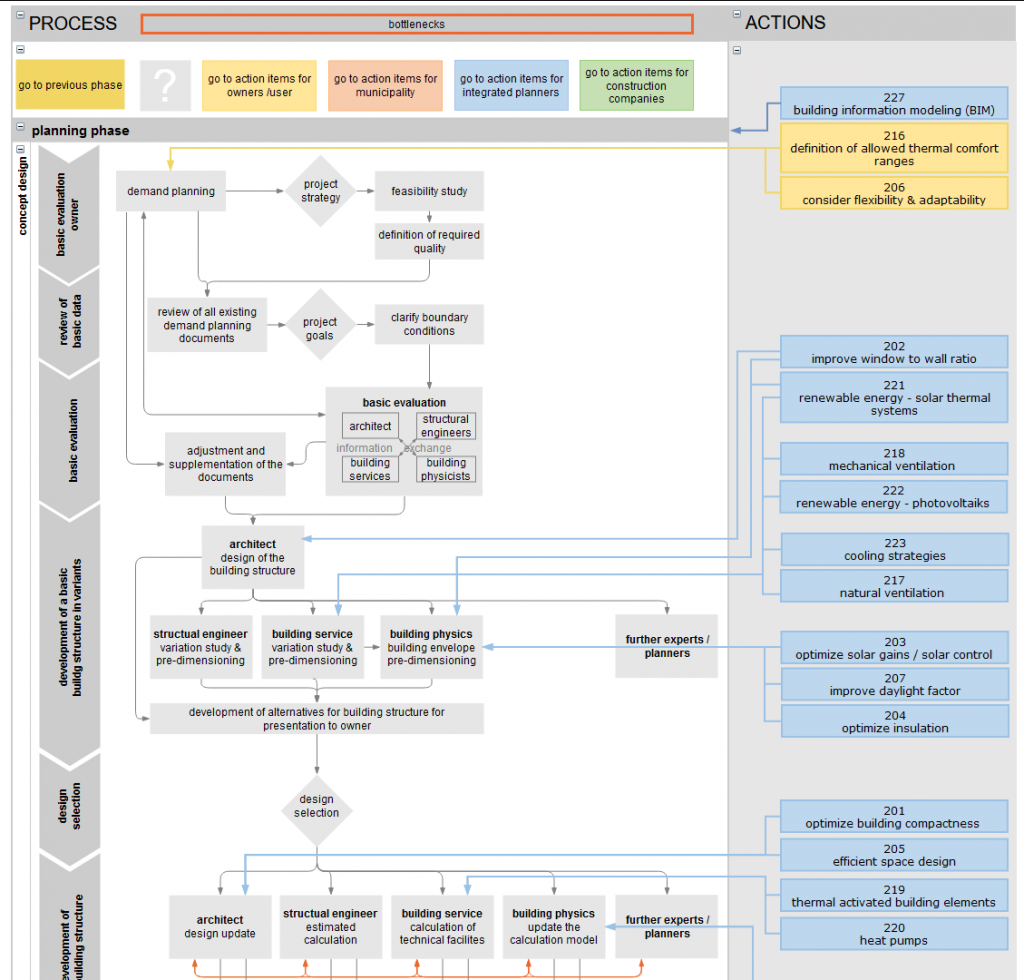

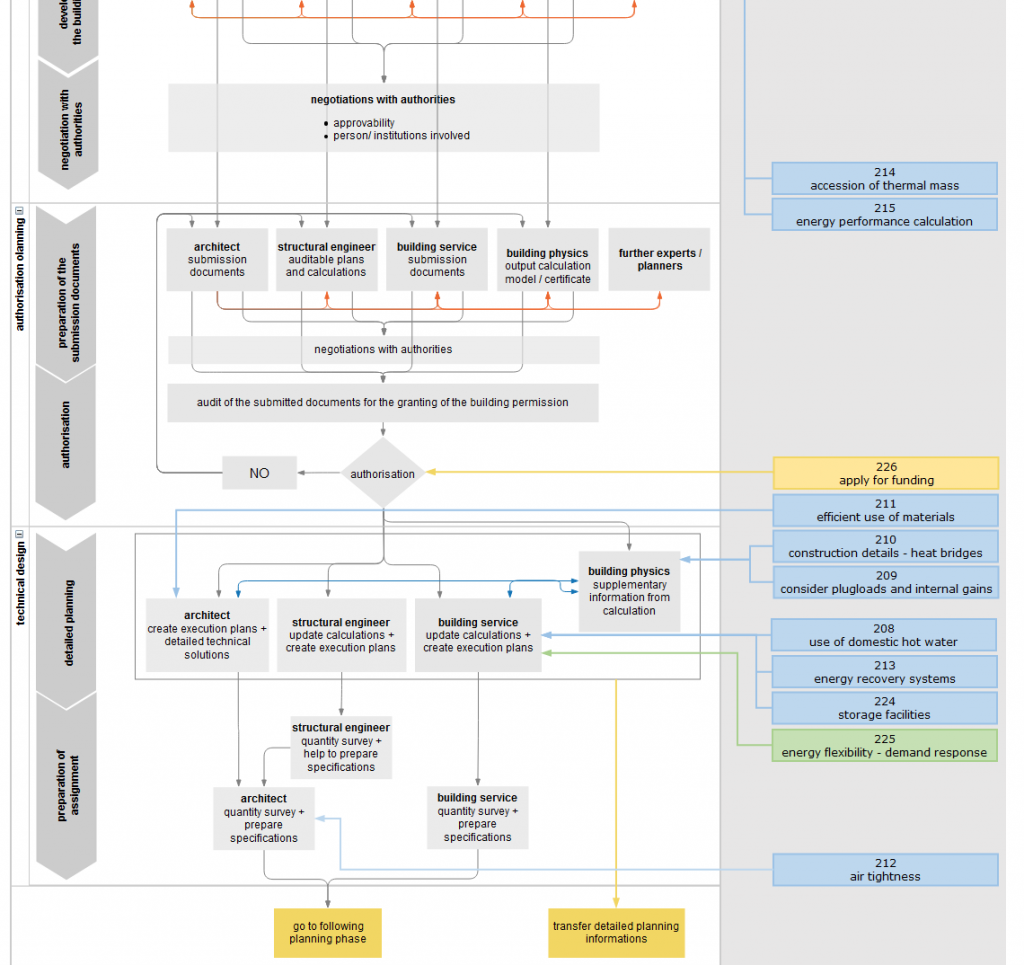

Integrated building design process

An integrated building

design process may have many definitions and meanings. In general, it may be considered a holistic approach, which considers the interactions between different actions, rather than optimizing them separately. E.g. optimizing building layout/plans from a user perspective may have major effects for the superstructure of the building, which in turn causes unnecessary additional costs.

The process must be supported by the entire design team. The outcome

of the process should be targeted to create a building with:

• High architectural

quality

• High energy

efficiency and low environmental impact

• Healthy indoor

climate

To be able to start the demand planning it is important to understand the client´s requirements and clearly define the project goals. It is central that the entire design team understands the goals of the project and understands that the work needs to be iterative and depends on cooperation. For projects with considerably higher goals, like nZEBs, the design process should start with a feasibility study showing important technical solutions, costs, savings and potential solution sets that work well together. This provides a basis for the decision of the main targets for the project.

The quality of the processes depends on the project organization and the information provided about project goals and framework conditions.

Only a simultaneous and comprehensive interdisciplinary project team can fully deal with the dependencies between function, form and energy and thus also identify and evaluate the manifold cost effects of actions in the process.

This applies in particular to the financial consequences of architectural decisions on energy costs that cannot be determined by the LCC calculation. Close and iterative cooperation also reduces information losses and planning collisions and thus prevents time- and cost-intensive planning loops.

The exchange of information between partners is becoming increasingly relevant with the growing complexity of construction projects. This is important because the main reason for planning errors and missed deadlines are inadequate and incorrect availability of information. Therefore, the definition of communication channels is of great importance for the reduction of data and time loss. Smooth and transparent communication is the key to efficient planning of nZEBs. This must be retained throughout the entire process, as subsequent decisions must be made based on all information from previous decisions and dependencies.

Integral planning is the prerequisite for a lifecycle-oriented process that meets the economic, ecological and socio-cultural objectives. Architects and engineers work simultaneously and team-oriented on the best innovative solution and constantly check if qualitative and quantitative goals are reached. A data model, building information modeling – BIM, maps the process from the initial idea to all virtual planning variants and the real construction processes to the lifelong operation of the building.

The integral design phase is divided into different phases, in which knowledge carriers from the different specialist areas come together. This development takes place in the investigation of variants and the evaluation of the different concepts based on ecological and economic considerations. The integral design method makes it possible to compare variants with each other and select the concept that corresponds to the objectives of the client and the target values.

When the authorization planning phase begins, the design team may have changed (new members come in and members may have left the team). It is therefore important to revisit and review the goals of the project, ensuring that goals and targets are understood by all members. During authorization planning, the final design is not defined in detail. However, in order to handle critical issues that may affect the project goals (identified in the concept design) some technical solutions may need to be studied in detail.

Also, this part of the process is iterative and depends on cooperation. Interdisciplinary work is crucial in this part of the process.

During technical design, the verification of the goals of the project is defined in detail.

As the commissioning tests are crucial for the outcome of the project, these tests need to be defined in this phase.

In order to manage information effectively, all members of the design team must have access to information (e.g. specifications, Gantt scheme, drawings etc.). This is effectively handled by using cloud-based management tools.

During the concept design, also critical pitfalls and bottlenecks which may affect the project goals need to be identified. Below, pitfalls and bottlenecks are listed that can endanger deadlines, budgets and quality of the nZEB project during the integrated building design process. The most common pitfalls and bottlenecks are:

- Demand planning client

- Integral planning

- Project management /-coordination

- Consulting expertise

- Tools

- Database

- New technologies

- Supply with (renewable)

energies - Subsidies

- Environmental engineering

services - Process definitions

- Information exchange /

cooperation

The following figure shows the

predominant activities in this phase again and also shows the actions that have

to be set at the appropriate time.

Figure: Integrated building design process with stakeholder related actions

A detailed description of all actions can be found in the ’Guideline

I – nZEB Processes’.

The following figure shows the correlations between the different actions and stakeholders.

Construction process

Considering the building as a manufactured product also allows the application of lean management strategies, which have been widely used in the industry sector (starting from automotive). In the building sector, there are only a few experiences, mainly performed in big and very complex construction sites but also in smaller, standardized and highly industrialized concepts (for example BoKlok, a housing product by IKEA and Skanska). CRAVEzero focuses on lean construction and operational protocols, which can also be applied for low and mid-rise investment for low LCC nZEBs.

Lean construction is an approach developed to improve the efficiency and effectiveness of the construction process. Managing a lean construction means minimizing the waste of time, resources and materials, and thereby maximizing value. The presence of a general contractor, which manages and coordinates all suppliers and operators, makes it possible to optimize the entire system through collaboration, the elimination of obstacles and to fluidize the process, to achieve the value desired by the customer.

A key premise for successful lean construction is that materials and tools are available when an operation is scheduled to start, equipment, design and people are in place. Breaking down the work and planning it with a focus on letting the different disciplines work separately as much as possible in an area and handling the interfaces between disciplines. This can be achieved by defining several “construction phases” and sequencing these.

The constructions have to reach the maximum functionality, with the satisfaction of the final users. Manufacturers and suppliers have to be involved in the design as soon as possible, to achieve integration and cost-effectiveness of the building. Current achievements, progress, compliance with project requirements must be verified by specific coordinated and continuous measures. Better is facilitating quality control throughout the construction process, rather than doing this at the end when correcting problems is much more difficult and expensive.

Allowing an open communication between owner, project manager, contractors and engineering consultants is an issue that guarantees a better outcome.

The use of prefabricated systems and the displacement of the workings as much as possible outside the building site is a winning strategy. Using this technology it is possible to apply the principles of lean production to construction. Off-site construction reduces on-site work and locates it mainly in the factory, allowing reorganization of technologies and processes aimed at greater efficiency and quality. The main improvements between the standard method of construction and the off-site are:

- Guarantee of better control and

quality of the product. Thanks to the

industrialized systems the production is optimized and the performances guaranteed; - Production times are reduced

thanks to the effectiveness and precision of production processes; - On-site operations are reduced

to a minimum, the risk of unforeseen events, delays and additional costs are

reduced; - The scheduled times and costs are

more certain, reduction of uncertainty to the realization of the projects.

The reliability of the goods produced, the traceability of the components, their programmable maintenance as well as the containment of the energy costs become aspects decisive for off-site construction.

Another strength of lean construction is the improvement of health, safety, environment and also job satisfaction (quality of working condition is improved, better cooperation and fewer conflicts are a guarantee)

Figure: Construction process with stakeholder related action

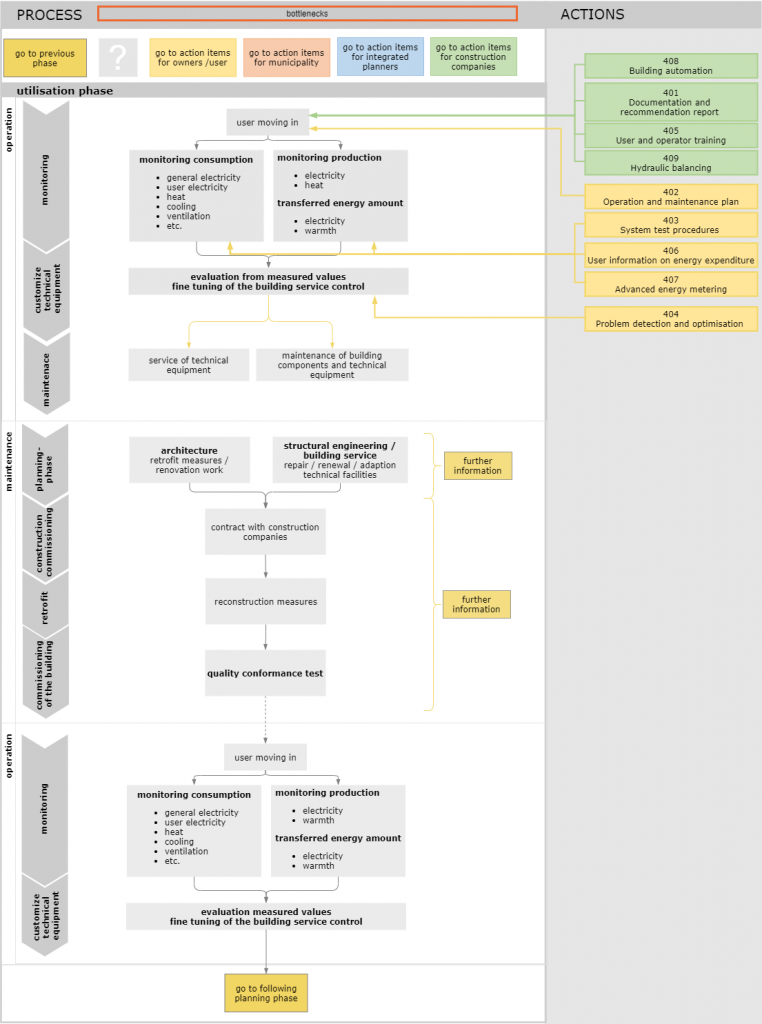

Building operation process

At the end of the construction process, once the building is commissioned, tested, certified and the user has moved in, it is important to ensure the proper building operation. Facilities’ operations and maintenance include a broad spectrum of processes, tools and services required to assure that the building will perform the functions for which it was designed and constructed. An appropriate user behaviour, occupant involvement, continuous monitoring and optimized maintenance raise the potential for cost reduction and savings. During the operation phase, the tenants and owners of the building are the main actors. An operation and maintenance plan can be used to ensure that the building functions in the manner defined in the planning phase. This includes component life expectancy, a plan for recurring operating and maintenance sessions, deceptive routines, target values and performance indicators, and a plan for recurring inspections of target values. Also, a complete and always up-to-date documentation of the building, services and the plant technology is required during operation to be able to control building services engineering and to exclude damage due to incorrect operation, care and maintenance. All facilities of the building require maintenance during its service life. It is possible to perform both planned preventive or predictive maintenance and corrective (repair)maintenance. Preventive Maintenance (PM) consists of a series of time- and IT-based maintenance requirements that provide a basis for planning,scheduling, and executing scheduled maintenance. PM includes lubricating,cleaning, adjusting and replacing components. Predictive Maintenance attempts to detect the onset of a degradation mechanism to correct it before the significant deterioration in the component or equipment. Corrective maintenance is a repair necessary to return the equipment to properly functioning condition or service and may be either planned or unexpected. Some equipment, at the end of its service life, may need an overhaul: a restoration to a completely service able condition as prescribed by maintenance serviceability standards.

Figure: Building operation process with stakeholder related actions

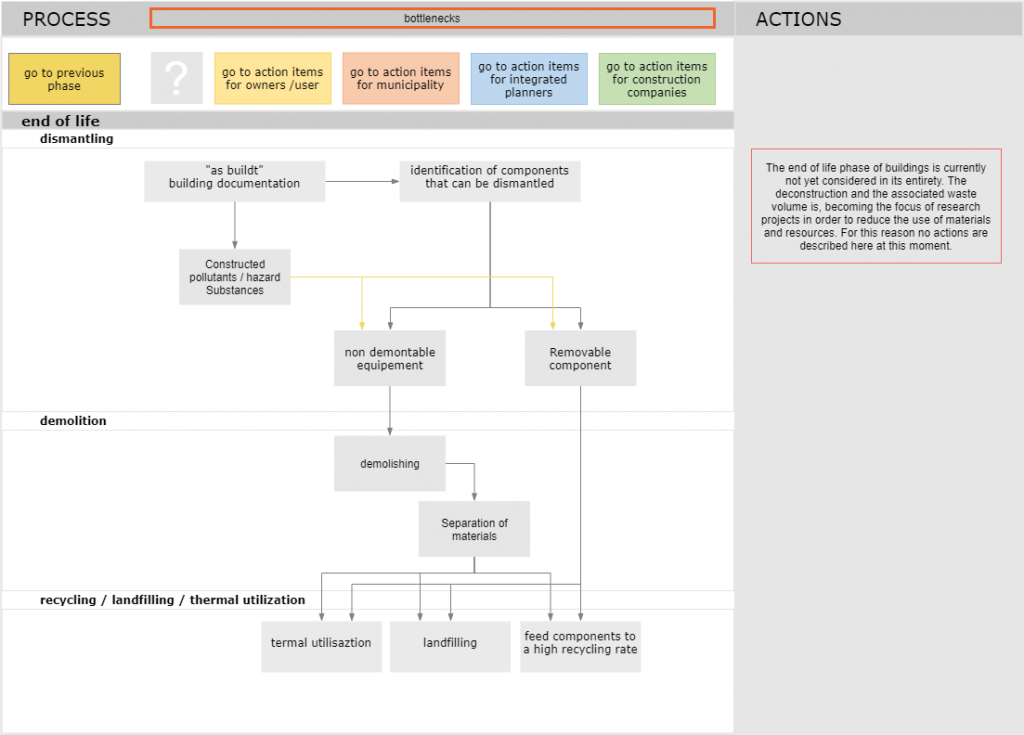

End of life

Figure: Building end of life process

Considering the building as a manufactured product also allows the application of lean management strategies, which have been widely used in the industry sector (starting from automotive). In the building sector, there are only a few experiences, mainly performed in big and very complex construction sites but also in smaller, standardized and highly industrialized concepts (for example BoKlok, a housing product by IKEA and Skanska). CRAVEzero focuses on lean construction and operational protocols, which can also be applied for low and mid-rise investment for low LCC nZEBs.

Lean construction is an approach developed to improve the efficiency and effectiveness of the construction process. Managing a lean construction means minimizing the waste of time, resources and materials, and thereby maximizing value. The presence of a general contractor, which manages and coordinates all suppliers and operators, makes it possible to optimize the entire system through collaboration, the elimination of obstacles and to fluidize the process, to achieve the value desired by the customer.

A key premise for successful lean construction is that materials and tools are available when an operation is scheduled to start, equipment, design and people are in place. Breaking down the work and planning it with a focus on letting the different disciplines work separately as much as possible in an area and handling the interfaces between disciplines. This can be achieved by defining several “construction phases” and sequencing these.

The constructions have to reach the maximum functionality, with the satisfaction of the final users. Manufacturers and suppliers have to be involved in the design as soon as possible, to achieve integration and cost-effectiveness of the building. Current achievements, progress, compliance with project requirements must be verified by specific coordinated and continuous measures. Better is facilitating quality control throughout the construction process, rather than doing this at the end when correcting problems is much more difficult and expensive.

Allowing an open communication between owner, project manager, contractors and engineering consultants is an issue that guarantees a better outcome.

The use of prefabricated systems and the displacement of the workings as much as possible outside the building site is a winning strategy. Using this technology it is possible to apply the principles of lean production to construction. Off-site construction reduces on-site work and locates it mainly in the factory, allowing reorganization of technologies and processes aimed at greater efficiency and quality. The main improvements between the standard method of construction and the off-site are:

Conclusion

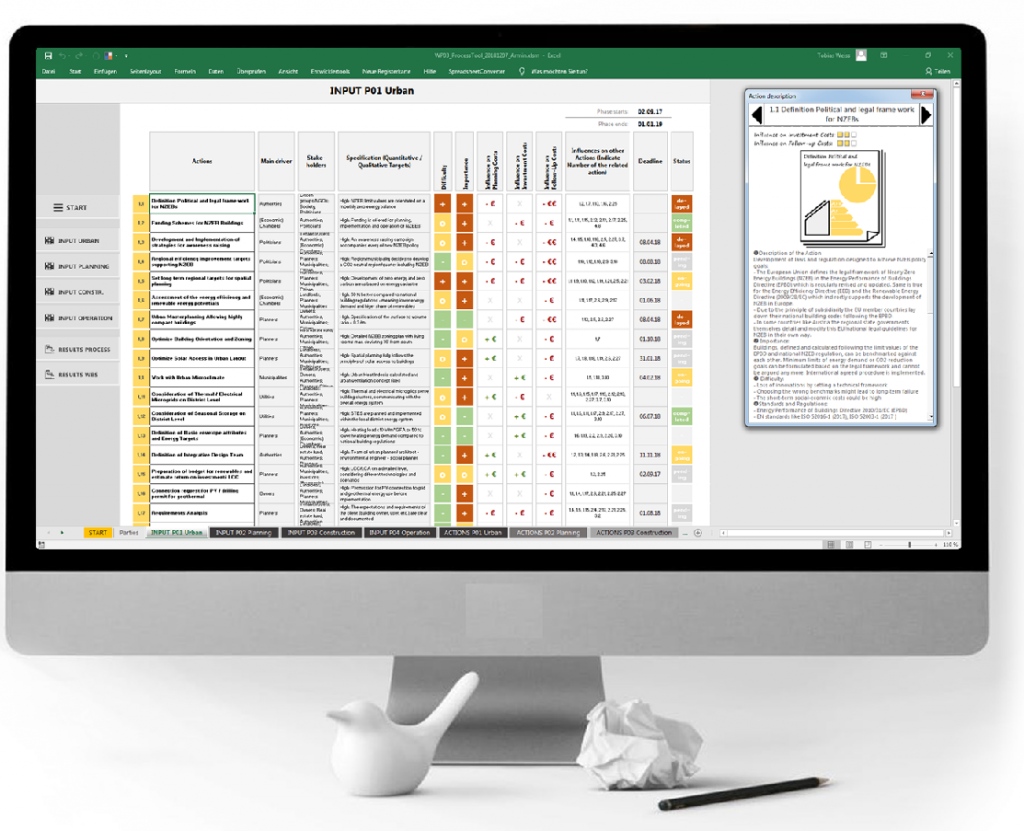

The focus of the described “CRAVEzero process”, is to promote a common, interdisciplinary understanding of the complexity of nZEB planning processes for all involved stakeholders. A well organized and transparent process is a key feature for achieving the goal of cost-optimal and sustainable nZEBs throughout the entire life cycle phase.

In the previous chapters this process was described. The overall life cycle process of briefing, designing, constructing and operating nZEBs was illustrated in different life cycle phases. Actions, stakeholder-relations, pitfalls and bottlenecks were pointed out in detail. Key actions needed to ensure the achievement of energy and cost related goals for replicable planning, design, construction, and operation process were presented.

Based on the results from this guideline and to further provide an operative methodology to achieve the best conditions towards cost optimal nZEBs all achieved results of the report have been summarized and structured in a “lean management protocol” the so-called “life cycle tracker tool”.

As a main result this report comes along with the downloadable “life cycle tracker tool”, an easy-to-use Excel file with VBA macros that combines project roles, actions, and design responsibility matrix. It is based on the experience of the whole consortium in the area of holistic project management with a focus on integral building planning of nZEBs. It gives support on how key performance parameters to achieve successful nZEBs should be prioritized and can be tracked along the whole life cycle process.

It helps stakeholders in different phases of the life cycle to structure the whole planning, construction and operation process in a framework ensuring a high process quality of new nZEBs.

It can be downloaded here: http://pinboard.cravezero.eu